Stainless Steel Flat Bar

Classification :

PRODUCT DETAILS

Stainless Steel Flat Bar Description

Stainless steel flat bar is a common use case for polished stainless steel, typically 304 stainless steel. Flat bars are used for various structural supports and functional elements, including braces, trim, frames, and more. These products are commonly used across a wide variety of industries, including construction and engineering, architecture, elevators and escalators, and more.

Stainless steel bar is a term used to describe stainless steel that is cut, rolled, or extruded to an elongated, yet solid shape. Bars may be round, rectangular, square, or formed into other shapes. Bars are distinct from tubes, which are hollow in the middle.

“Flat bar” refers to bars that have a rectangular shape—that is, bars which are significantly wider than they are thick. Polished stainless steel is commonly used for flat bar applications.

Product Parameters

|

Product Name |

Stainless Steel Flat Bar |

|

|

Type |

Steel Bar |

|

|

Outer Diameter |

1/2 "to 10", Thickness: 2mm-150mm, Can provide customized | |

|

Length |

4 to 6 meters, or as customer's requirements | |

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

|

Surface |

Black, Bright Polished, Rough Turning, Mattness Surface Treatment, No. 4. BA, etc. |

|

|

Scope of Application |

The use cases for stainless steel flat bars—both mirror polished and with satin finishes—are varied, but primarily structural or functional in nature. For instance, flat bars are commonly used for bracing and structural supports within architectural or construction projects, or for building various types of frames. |

|

Chemical Composition

| Element | C | Cr | Mn | Ni | P | S | Si |

|---|---|---|---|---|---|---|---|

| SS 304 | 8.0 – 11.0 | 18.0 – 20.0 | 2.0 max | 8.0 – 11.0 | 0.045 max | 0.03 max | 1.0 max |

| SS 304L | 8.0 – 11.0 | 18.0 – 20.0 | 2.0 max | 8.0 – 12.0 | 0.045 max | 0.03 max | 1.0 max |

| SS 316 | 0.08 | 18.0 | 2.00 | 14.0 | 0.045 max | 0.03 max | 0.75 max |

| SS 316L | 0.08 | 18.0 | 2.00 | 14.0 | 0.045 max | 3.00 max | 0.10 max |

Use Cases for Stainless Steel Flat Bars

The use cases for stainless steel flat bars—both mirror polished and with satin finishes—are varied, but primarily structural or functional in nature. For instance, flat bars are commonly used for bracing and structural supports within architectural or construction projects, or for building various types of frames.

When it comes to more visual or ornamental applications, stainless steel flat bar is less common, but still seen relatively often. In these cases, flat bars may be used for decorative trim using a more mirror polished finish. Meanwhile, some use cases for stainless steel flat bars blend both function and form, such as for safety railings within elevators and escalators.

Broadly speaking, stainless steel flat bar is most commonly seen within the following industries:

● Construction and engineering

● Architecture and design

● Manufacturing, particularly for machines and automobiles

| No | 中国 | 日本 | 美国 | 韩国 | 德国 | 印度 | 澳大利亚 | 中国台湾 | |

| GB | JIS | ASTM | UNS | KS | DIN | BIS | AS | CNS | |

| 奥氏体不锈钢 | |||||||||

| 1 | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | - | 202 |

| 3 | 12Cr17Ni7 | SUS301 | 301 | S20200 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

| 7 | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

| 8 | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

| 9 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

| 10 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

| 11 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

| 12 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | ~02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

| 16 | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

| 17 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

| 18 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

| 19 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

| 20 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

| 21 | 06Cr18Ni11Ti S | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.4550 | 04Cr18Ni10Nb40 | 347 | 347 |

| 双相不锈钢 | |||||||||

| 1 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | - | 329J1 | - |

| 2 | 022Cr23Ni5Mo3N | - | S32205 | F60 | - | 1.4462 | - | 2205 | 2205 |

| 3 | 022Cr25Ni7Mo4N | - | S32750 | F53 | - | 1.4410 | - | 2507 | 2507 |

| 铁素体不锈钢 | |||||||||

| 1 | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 2 | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L |

| 3 | 022Cr12 | SUS410L | - | - | STS410L | - | - | 410L | 410L |

| 4 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 5 | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 |

| 6 | 022Cr18NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 |

| 7 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | - | 444 | 444 |

| 马氏体不锈钢 | |||||||||

| 1 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | - | - | 403 | 403 |

| 2 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 3 | 20Cr13 | SUS420J1 | 410 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 4 | 30Cr13 | SUS420J2 | - | - | STS420J2 | 1.4028 | 30 Cr13 | 420J2 | 420J2 |

| 5 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | - | - | 440A | 440A |

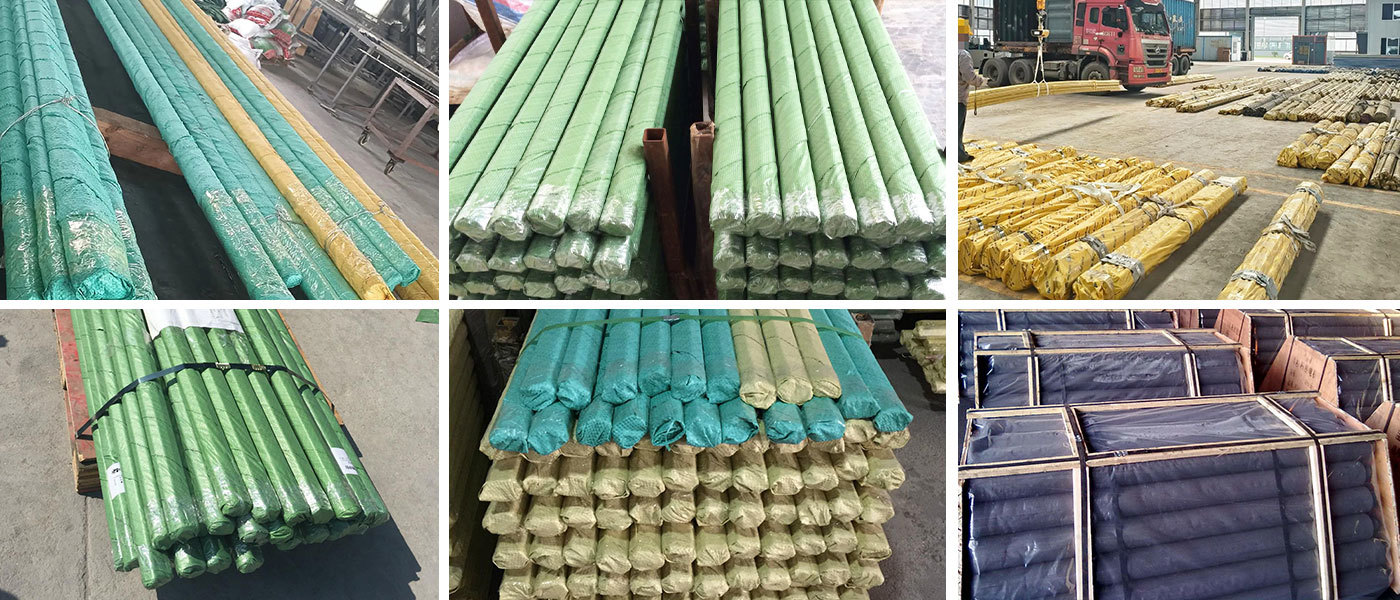

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

CUSTOMER VISIT

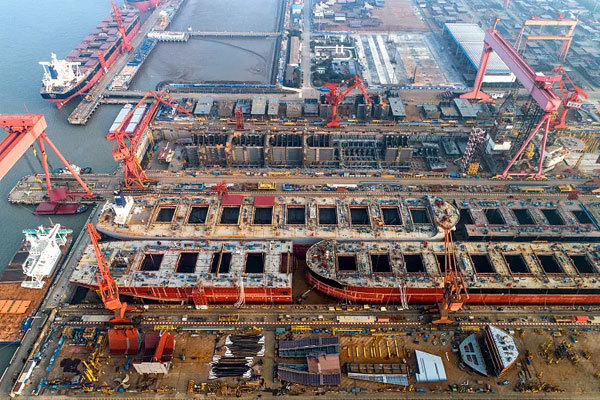

Its products are exported to over 100 countries and regions, with production, sales, and export volumes consistently ranking among the highest in China.

QUALITY INSPECTION

The company has introduced world-leading equipment for ironmaking, steelmaking, tube rolling, tube processing, heat treatment, and non-destructive testing.

FACTORY WORKSHOP

Its 7 rolling facilities cover all 4 types of seamless piperolling equipment, which are MPM, PQF, ASSEL and REM. Among these rolling facilities, the high precision 3-roll continuous rolling mill – PQF (Premium Quality Finishing).

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

APPLICATION AREAS

Pipeline transportation

Aviation and railways

Maritime transport

Petrochemical

Pipeline transportation

Aviation and railways

FAQ

Q1:Can you send samples?

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

Q4:What about product prices information?

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

GET A FREE QUOTE