Color Coated Galvalume Steel Coil PPGL

Classification :

PRODUCT DETAILS

Color Coated Galvalume Steel Coil PPGL Description

PPGL steel is a durable, colorful and economical building material. It is the abbreviation of color coated aluminum-zinc plated steel coil, which is based on aluminum-zinc plated steel coil. The aluminum-zinc coated steel is then continuously painted in coil form. Due to its heat resistance and corrosion resistance, it has become a material for various construction purposes, especially roofs and walls. Because it contains 55% aluminum, the corrosion resistance of PPGL coil is much better than that of PPGI, which can greatly extend the service life.

Product Parameters

Product Name | Color Coated Galvalume Steel Coil PPGL |

Thickness | 0.13mm-0.8mm |

Width | 600mm-1250mm |

Length | Support Customization |

Color | According RAL Color Card (Can provide custom pattern) |

Paint | PE, SMP, HDP, PVDF |

Primer | Epoxy primer, Polyester primer, Water soluble acrylic primer, Polyurethane primer |

Coating Thickness | Top Coat: 10-30mic, Back Paint: 5-25mic |

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

PPGL Color Coated Coil Advantages

Excellent Corrosion Resistance

Because it contains 55% aluminum, the corrosion resistance of PPGL is much better than that of PPGI, which can greatly extend the service life.

Good Heat Reflectivity

Good heat resistance can keep the building cool in the hot summer.

Weather Resistance

Pre-coated aluminum-zinc steel can withstand severe weather conditions, such as extreme summer, winter or rainfall.

Good Processing Performance

PPGL steel plate is easy to shear, profiling, blanking and other processing.

Beautiful Appearance

They have a pleasing surface finish and aesthetics that look attractive and impressive.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester Smp

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Scope of Application

Construction industry: such as roof, interior and exterior wall panels, balcony panels, suspended ceilings, partition walls, windows, door panels, etc.

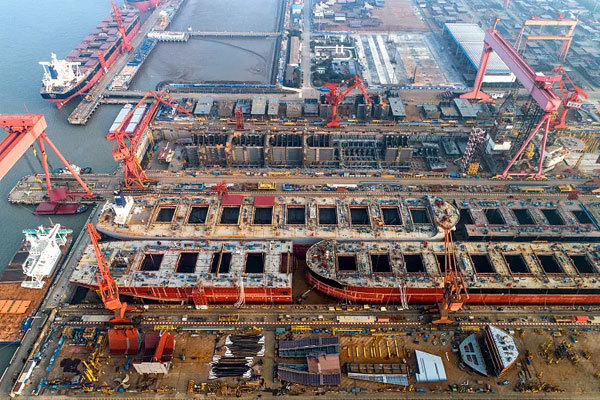

Transportation: For example, car trim panels, train or ship decks, containers, etc.

Electrical equipment: mainly used for making freezers, washing machines, air conditioners and other enclosures. PPGI coils for home appliances have the best quality and the highest production requirements.

Furniture: such as wardrobes, lockers, radiators, lampshades, tables, beds, bookcases, shelves, etc.

Other industries: such as roller shutters, billboards, traffic signs, elevators, whiteboards, etc.

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

CUSTOMER VISIT

Its products are exported to over 100 countries and regions, with production, sales, and export volumes consistently ranking among the highest in China.

QUALITY INSPECTION

The company has introduced world-leading equipment for ironmaking, steelmaking, tube rolling, tube processing, heat treatment, and non-destructive testing.

FACTORY WORKSHOP

Its 7 rolling facilities cover all 4 types of seamless piperolling equipment, which are MPM, PQF, ASSEL and REM. Among these rolling facilities, the high precision 3-roll continuous rolling mill – PQF (Premium Quality Finishing).

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

APPLICATION AREAS

Pipeline transportation

Aviation and railways

Maritime transport

Petrochemical

Pipeline transportation

Aviation and railways

FAQ

Q1:Can you send samples?

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

Q4:What about product prices information?

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

GET A FREE QUOTE