Galvanized Channel Steel

Classification :

PRODUCT DETAILS

Galvanized Channel Steel Description

Hot-dip galvanized channel steel is also called hot-dip galvanized channel steel and hot-dip galvanized channel steel. It is an effective metal anti-corrosion method and is mainly used in metal structural facilities in various industries. It is to immerse the channel steel after derusting in the molten zinc of about 440~460 ℃, so that the zinc layer is attached to the surface of the channel steel, thus achieving the purpose of anti-corrosion. Now the main method of galvanizing the surface of the channel steel is hot dip galvanizing.

Product Parameters

| Material | A36, St37, S235J0, S235J2, St52, S355JR, Q195, Q215, Q235B, Q345B, S235JR, S355JR, S355, SS440, SM400A, SM400B, A572 GR50/GR60, SS540 |

| Scope of Production | 50*37*4.5-400*104*14.5, 75*40*3.8*7-152*76*6.4*9, 140*60*7*10-200*75*8.5*11.5 |

| Length | 6m, 9m, 12m or according to customer requirements |

| Technology | Hot Rolled, Welded |

| Standard | ASTM, AISI, JIS, GB, DIN, EN |

| Surface | Galvanized, Painted or according to your requirements |

| Supply Capacity | 2000 tons/Day |

| Business Type | Manufacturer |

| Certificate | ISO, SGS, BV |

| Application | Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

| Loading Port | Any Port in China |

| Packaging | Standard export packing or as your request |

| Payment Method | Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

CUSTOMER VISIT

Its products are exported to over 100 countries and regions, with production, sales, and export volumes consistently ranking among the highest in China.

QUALITY INSPECTION

The company has introduced world-leading equipment for ironmaking, steelmaking, tube rolling, tube processing, heat treatment, and non-destructive testing.

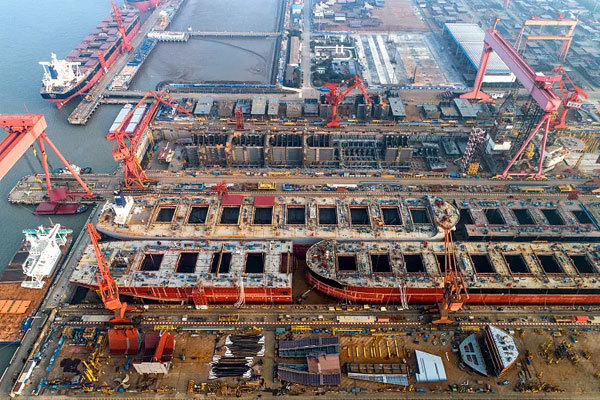

FACTORY WORKSHOP

Its 7 rolling facilities cover all 4 types of seamless piperolling equipment, which are MPM, PQF, ASSEL and REM. Among these rolling facilities, the high precision 3-roll continuous rolling mill – PQF (Premium Quality Finishing).

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

APPLICATION AREAS

Pipeline transportation

Aviation and railways

Maritime transport

Petrochemical

Pipeline transportation

Aviation and railways

FAQ

Q1:Can you send samples?

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

Q4:What about product prices information?

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

GET A FREE QUOTE