A179 Seamless Steel Tube

Classification :

PRODUCT DETAILS

A179 Seamless Steel Tube Description

A179 seamless steel pipe is a commonly used steel pipe material, and its implementation standard is ASTMA179/A179M. This standard applies to seamless carbon steel and alloy steel tubes for heaters, boilers and heat exchangers. the ASTM A179/A179M standard requires that the chemical composition of the pipe meet specific requirements to ensure that the material of the pipe meets specific standards and has good weldability and mechanical properties. From the point of view of mechanical properties, the standard specifies the mechanical performance indicators such as tensile strength, yield strength and elongation of the pipe to ensure that the pipe has sufficient strength and toughness during use.

Product Parameters

|

Product Name |

A179 Seamless Steel Tube |

|

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI etc. |

|

|

Outer Diameter |

Seamless: 1/4"-36" |

Welding: 21.3mm-3620mm |

|

Round Tube: 1/2"-10" |

Square Tube/Rectangular Tube: 15x15mm-400x600mm |

|

|

Wall Thickness |

Seamless: 1.25mm-50mm |

Welding: 1.65mm-65mm |

|

Length |

3-12 meters, Support customization |

|

|

Surface Process |

Bright, Polished, Black |

|

|

Other Services |

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. |

|

Chemical Composition

|

C |

Mn |

P≤ |

S≤ |

Si≤ |

|

0.06-0.18 |

0.27-0.63 |

0.035 |

0.035 |

0.25 |

Mechanical Properties

|

Steel Standard |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

Elongation(%) |

|

A179 |

≥180 |

≥ 325 |

≥ 35 |

Scope of Application

ASTM A179 covers seamless cold drawn low carbon steel pipe with minimum wall thickness for piping, heat exchangers, condensers and other heat transfer services.

Standard of carbon steel pipe

| API 5L | for use in conveying gas, water, and oil in the natural gas and oil industries, and covers seamless and welded steel line pipe. |

| API 5CT | for casing and tubing |

| ASTM A53 | for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless |

| ASTM A106 | for Seamless Carbon Steel Pipe for High-Temperature Service |

| ASTM A179 | for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

| ASTM A192 | for Seamless Carbon Steel Boiler Tubes for High-Pressure Service |

| ASTM A213 | for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| ASTM A252 | for Welded and Seamless Steel Pipe Piles |

| ASTM A333 | for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness |

| ASTM A672 | for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

| ASTM A335 | for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

| DIN 17175 | seamless steel pipes are used in boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices. |

| DIN 1629 | specifies the Seamless Circular Tubes of Non Alloys Steels with Special Quality Requirements. |

| DIN 2391 | for Cold Drawn High Precision Seamless Tube |

| DIN 2458 | Welded Steel Pipes in Unalloyed and Low Alloy Steels for Supply Purposes |

| EN 10210 | Seamless steel tubes for pressure purposes |

| BS 3059 | Steel boiler and superheater tubes |

| JIS G3454 | Carbon steel pipes for pressure service |

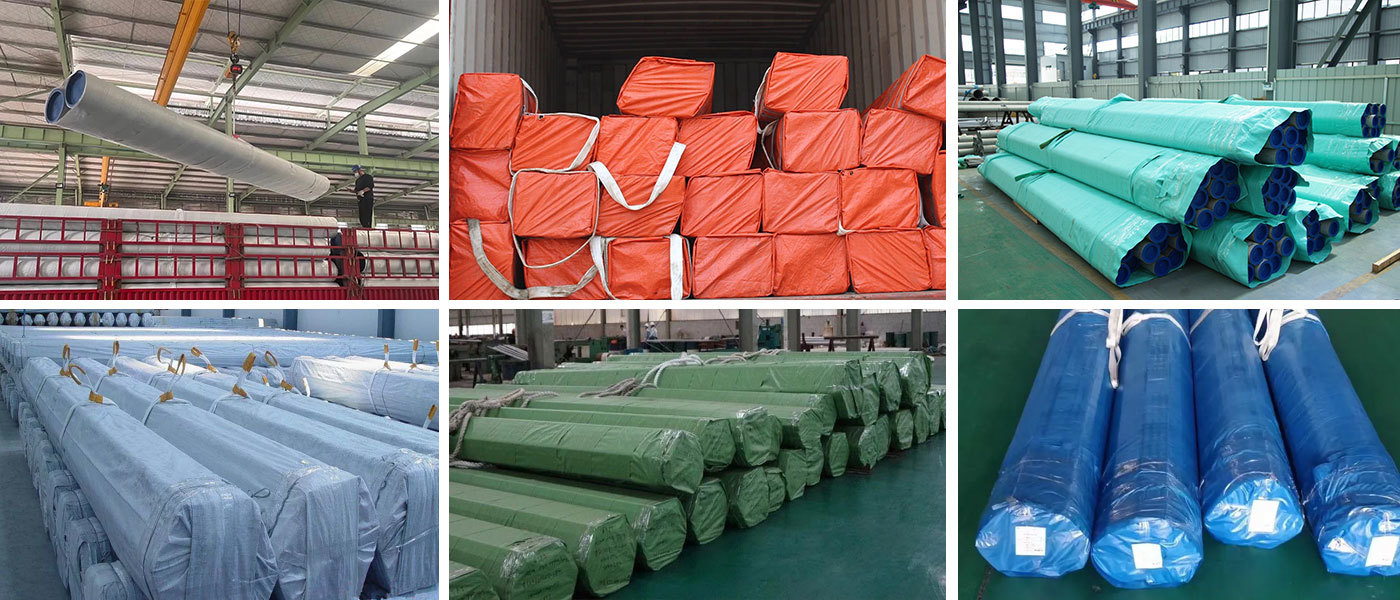

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

CUSTOMER VISIT

Its products are exported to over 100 countries and regions, with production, sales, and export volumes consistently ranking among the highest in China.

QUALITY INSPECTION

The company has introduced world-leading equipment for ironmaking, steelmaking, tube rolling, tube processing, heat treatment, and non-destructive testing.

FACTORY WORKSHOP

Its 7 rolling facilities cover all 4 types of seamless piperolling equipment, which are MPM, PQF, ASSEL and REM. Among these rolling facilities, the high precision 3-roll continuous rolling mill – PQF (Premium Quality Finishing).

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

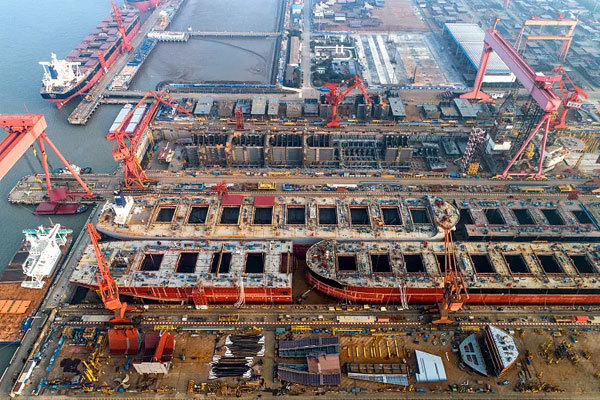

APPLICATION AREAS

Pipeline transportation

Aviation and railways

Maritime transport

Petrochemical

Pipeline transportation

Aviation and railways

FAQ

Q1:Can you send samples?

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

Q4:What about product prices information?

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

GET A FREE QUOTE