Hastelloy C-22 Pipe

Classification :

PRODUCT DETAILS

Hastelloy C-22 Pipe Description

The main elements of Hastelloy C22 pipe include cobalt, chromium, tungsten, molybdenum and small amounts of aluminum, titanium and nitrogen. Cobalt element improves the strength and hardness of the alloy, chromium element has an important impact on the corrosion resistance of the alloy, tungsten and molybdenum can increase the high-temperature strength of the alloy. Moreover, the addition of aluminum and titanium elements can refine the grains and improve the toughness of the alloy, while the addition of nitrogen can improve the strength and corrosion resistance of the alloy. Besides, it has good plasticity and toughness and can work with both cold and hot processing. Hastelloy C22 pipe also features excellent oxidation resistance and creep resistance at high temperatures. Hastelloy C22 pipes are commonly used in aerospace, chemical industry, petroleum and other fields because of its excellent corrosion resistance and high temperature strength.

Product Parameters

Product Name | Hastelloy C-22 Pipe | |

Outer Diameter | Round Pipe | 4mm-200mm |

Square Pipe | 10*10mm-100*100mm | |

Rectangular Pipe | 10*20mm-50*100mm | |

Wall Thickness | 0.6mm-6.0mm | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, No.4, BA, etc. | |

Certificate | ISO, SGS, BV | |

Production Technology | Hot Rolling, Cold Rolling | |

Chemical Composition

C | Si | P | S | V | Cr | Mn | Fe | Co | Ni | Mo | W |

0.015 max | 0.08 max | 0.02 max | 0.02 max | 0.35 max | 20.0 - 22.5 | 0.50 max | 2.0-6.0 | 2.5 max | Remainder | 12.5 - 14.5 | 2.5 - 3.5 |

Mechanical Properties

Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

100 | 45 | 45 |

Physical Performance

| Units | Temperature in°C |

Density | 8.69 g/cm³ | 24°C |

Specific Heat | 0.093 Kcal/kg.C | 52° |

Melting Range | 1357-1399°C | - |

Modulus of Elasticity | 205.5 KN/mm² | - |

Electrical Resistivity | 113.7 µΩ.cm | 24 ° |

Coefficient of Expansion | 12.4 µm/m °C | 24-93° |

Thermal Conductivity | 10.1 w/m-° K | 48° |

Scope of Application

C- 276 alloy is used in pesticide production, phosphoric acid production, pickling system, plate heat exchanger, selective leaching system, SO2 cooling tower, sulfonation system, shell and tube heat exchanger, surfacing welding valve, etc.

|

|

|

EN |

UNS |

|

Hastelloy |

|||

| Alloy C-276 |

Hastelloy C-276 |

2.4819 |

N10276 |

| Alloy C-22 |

Hastelloy C-22 |

2.4602 |

N06022 |

| Alloy B2 |

Hastelloy B2 |

2.4617 |

N10665 |

| Alloy B3 |

Hastelloy B3 |

2.4600 |

N01675 |

| Alloy X |

Hastelloy X |

2.4655 |

N06002 |

| Monel | |||

| Alloy 400 |

Monel 400 |

2.4360 |

N04400 |

| Alloy R-405 |

Monel R-405 |

- |

N04405 |

| Alloy K-500 |

Monel K-500 |

2.4375 |

N05500 |

| Inconel | |||

| Alloy 600 |

Inconel 600 |

2.4816 |

N06600 |

| Alloy 601 |

Inconel 601 |

2.4851 |

N06601 |

| Alloy 625 |

Inconel 625 |

2.4856 |

N06625 |

| Alloy 718 |

Inconel 718 |

1.4668 |

N07718 |

| Incoloy | |||

| Alloy 800 |

Incoloy 800 |

1.4876 |

N08800 |

| Alloy 800H / 800HT |

Incoloy 800H / 800HT |

1.4958 / 1.4959 |

N08810 / N08811 |

| Alloy 825 |

Incoloy 825 |

2.4858 |

N08825 |

| Alloy 925 |

Incoloy 925 |

- |

N09925 |

| Alloy DS |

Incoloy DS |

- |

- |

| Nickel | |||

| Alloy 200 |

Nickel 200 |

2.4066 |

N02200 |

| Alloy 201 |

Nickel 201 |

2.4068 |

N02201 |

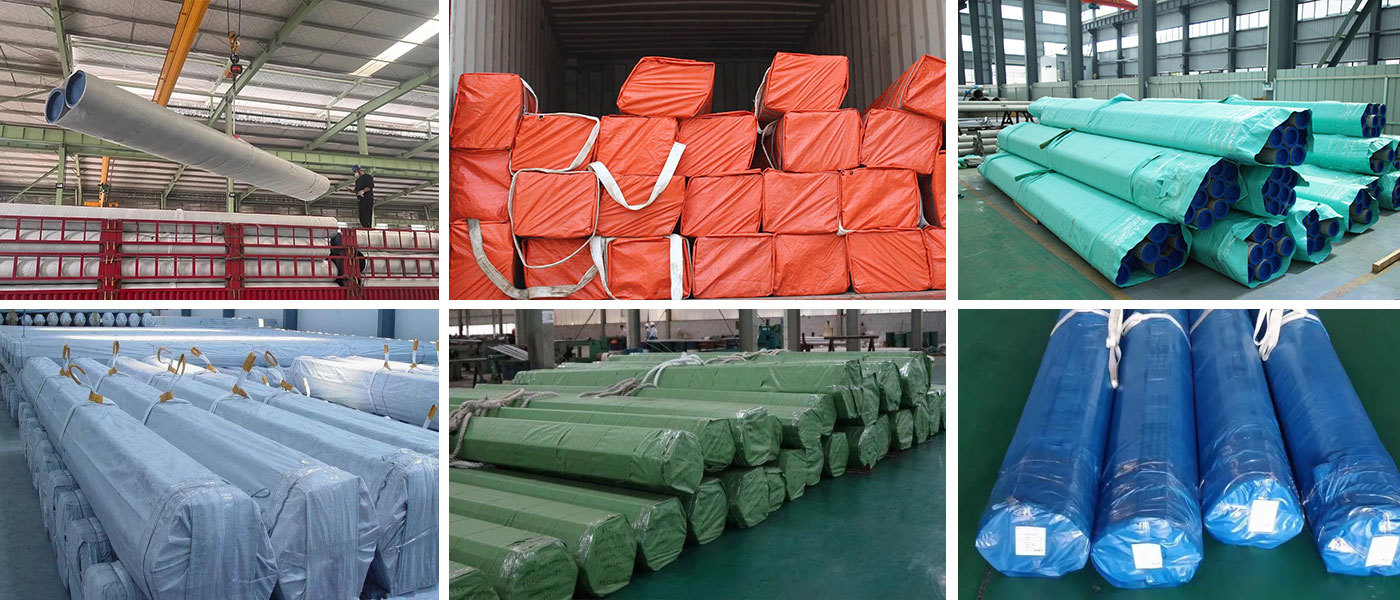

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

CUSTOMER VISIT

Its products are exported to over 100 countries and regions, with production, sales, and export volumes consistently ranking among the highest in China.

QUALITY INSPECTION

The company has introduced world-leading equipment for ironmaking, steelmaking, tube rolling, tube processing, heat treatment, and non-destructive testing.

FACTORY WORKSHOP

Its 7 rolling facilities cover all 4 types of seamless piperolling equipment, which are MPM, PQF, ASSEL and REM. Among these rolling facilities, the high precision 3-roll continuous rolling mill – PQF (Premium Quality Finishing).

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

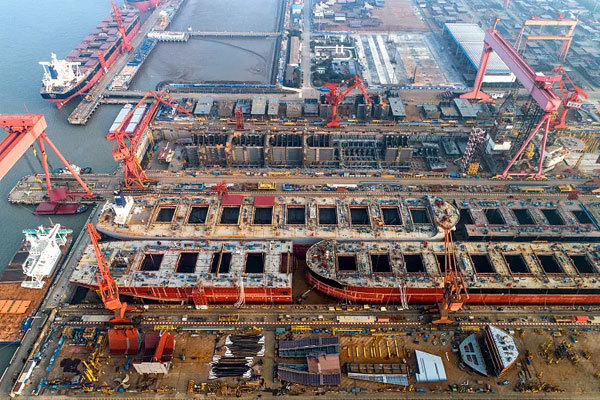

APPLICATION AREAS

Pipeline transportation

Aviation and railways

Maritime transport

Petrochemical

Pipeline transportation

Aviation and railways

FAQ

Q1:Can you send samples?

Q2:What product information do I need to provide?

Q3:It's my first time to import steel products, can you help me with it?

Q4:What about product prices information?

Q5:What ports of shipment are there?

Q6:What is your terms of payment ?

RELATED PRODUCTS

GET A FREE QUOTE